REFERENCES

Palm oil factory

Plant 1

Plant 2

Plant 3

Plant 4

Plant 5

Plant 6

Plant 7

Plant 8

Plant 9

Plant 10

Plant 11

Plant 12

Plant 1

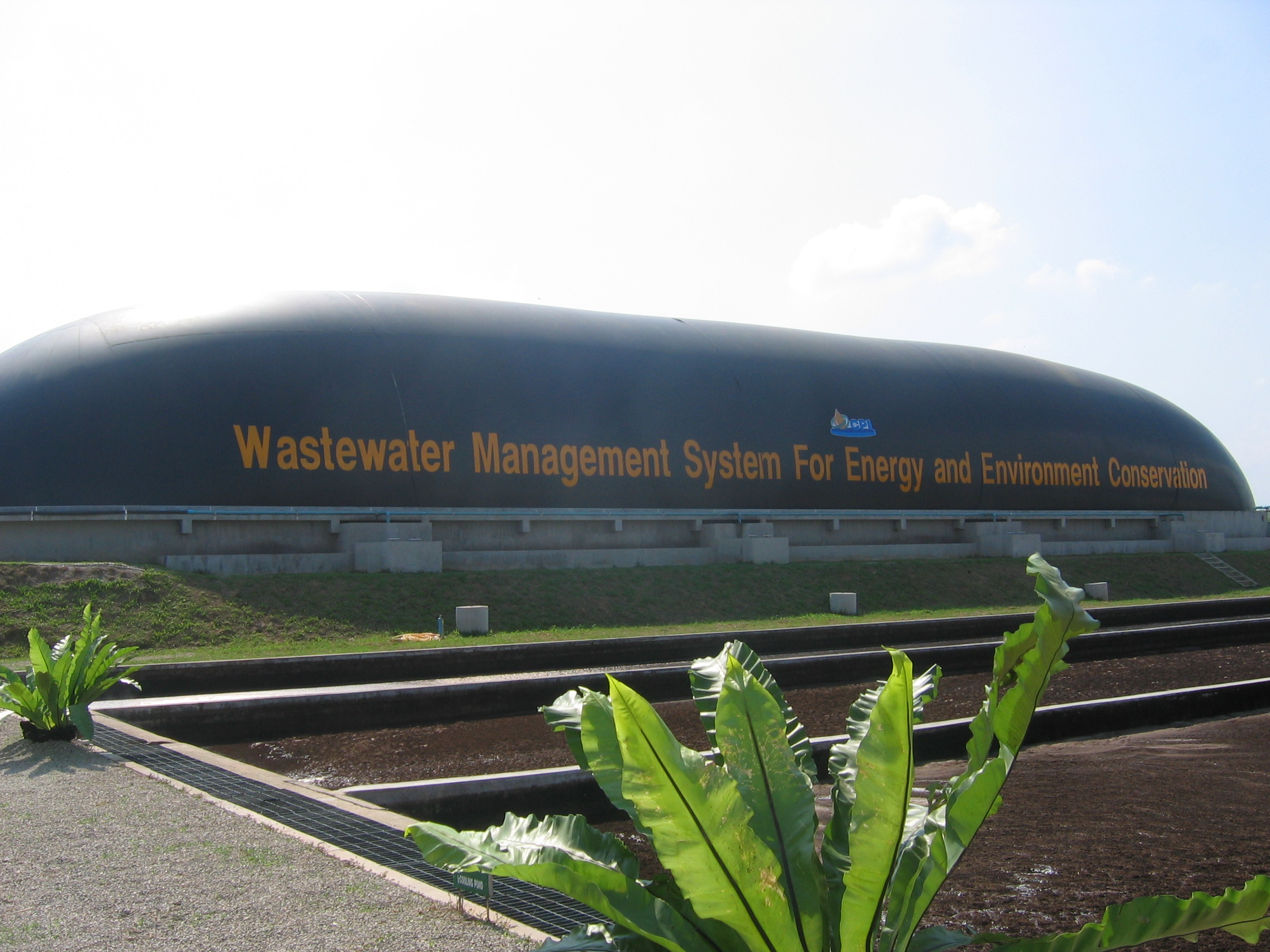

1. Palm oil effluent management system

| Title | Infomation |

|---|---|

| Year | 2005 – 2007 |

| Company name | Chumphon Palm Oil Industry Pub Co., Ltd. (CPI) |

| Location | Chumphon province, Thailand |

| Raw materials | Palm oil mill effluent, production capacity of 60 tons FFB/hour or 1,500 tons FFB/d |

| Technology | A+ CSTR, A+ UASB |

| Biogas production | 22,000 m3/d at full capacity |

| Gas utilization | Replacing biomass and fossil fuel for heat production |

| Financial support | Registered CDM project |

Plant 2

2. Palm oil mill effluent and decanter cake management system

| Title | Infomation |

|---|---|

| Year | 2008 – 2010 |

| Company name | Vichitbhan Palmoil Pub Co., Ltd. |

| Location | Ta Sae, Chumphon province, Thailand |

| Raw materials | Palm oil mill effluent and decanter cake, production capacity of 120 tons FFB/hour or 3,000 tons FFB/d |

| Technology | A+ CSTR, A+ UASB, A+ HCSR |

| Biogas production | 52,000 m3/d at full capacity |

| Gas utilization | Replacing 5 MW electricity – grid connection |

| Financial support | Registered CDM project |

Plant 3

3. Palm oil mill effluent and decanter cake management system

| Title | Infomation |

|---|---|

| Year | 2008 – 2010 |

| Company name | Vichitbhan Palmoil Pub Co., Ltd. |

| Location | Tung ka, Chumphon province, Thailand |

| Raw materials | Palm oil mill effluent and decanter cake, production capacity of 75 tons FFB/hour or 1,800 tons FFB/d |

| Technology | A+ CSTR, A+ UASB, A+ HCSR |

| Biogas production | 30,000 m3/d at full capacity |

| Gas utilization | Replacing 3 MW electricity – grid connection |

| Financial support | Registered CDM project |

Plant 4

4. Palm oil mill effluent and decanter cake management system

| Title | Infomation |

|---|---|

| Year | 2012 – 2014 |

| Company name | Chumphon Palm Oil Industry Pub Co., Ltd. (CPI) |

| Location | Chumphon province, Thailand |

| Raw materials | Additional 30 tons FFB/hour and design reactor for decanter cake |

| Technology | A+ CSTR, A+ UASB, A+ HCSR |

| Biogas production | 28,000 m3/d at full capacity |

| Gas utilization | Heat and power |

| Financial support | Registered CDM project |

Plant 5

5. Palm oil mill effluent management system

| Title | Infomation |

|---|---|

| Year | 2013 – 2015 |

| Company name | Jeng Huat (Bahau) Realty Sdn. Bhd |

| Location | Pahang, Malaysia |

| Raw materials | Palm oil mill effluent |

| Technology | A+ CHCR, A+ UASB |

| Biogas production | 14,000 m3/d at full capacity |

| Gas utilization | Replacing 1.2 MW electricity – grid connection |

| Financial support | Energy Conservation Promotion Fund, Malaysia |

Plant 6

6. Palm oil mill effluent management system

| Title | Infomation |

|---|---|

| Year | 2013 – 2015 |

| Company name | The Natural Palm Group Co.,Ltd. |

| Location | Chumphon province, Thailand |

| Raw materials | Palm oil mill effluent and decanter cake |

| Technology | A+ CSTR |

| Biogas production | 14,000 m3/d at full capacity |

| Gas utilization | Replacing 1.2 MW electricity – grid connection |

| Financial support | Energy Conservation Promotion Fund, Thailand |

Plant 7

7. Palm oil decanter cake management system

| Title | Infomation |

|---|---|

| Year | 2013 – 2015 |

| Company name | The Natural Palm Oil Co., Ltd. |

| Location | Surat Thani province, Thailand |

| Raw materials | Decanter cake |

| Technology | A+ HCSR |

| Biogas production | 12,000 m3/d at full capacity |

| Gas utilization | Replacing 500 kW electricity – grid connection |

| Financial support | Energy Conservation Promotion Fund, Thailand |

Plant 8

8. Palm oil mill effluent management system

| Title | Infomation |

|---|---|

| Year | 2013 – 2016 |

| Company name | Felda Engineering Services Sdn. Bhd |

| Location | Sabah, Malaysia |

| Raw materials | Palm oil mill effluent |

| Technology | A+ CHCR, A+ UASB |

| Biogas production | 28,000 m3/d at full capacity |

| Gas utilization | Replacing 2.4 MW electricity – grid connection |

| Financial support | Energy Conservation Promotion Fund, Malaysia |

Plant 9

9. Palm oil mill effluent and decanter cake management system

| Title | Infomation |

|---|---|

| Year | 2014 – 2016 |

| Company name | The Natural Palm Group Co., Ltd. |

| Location | Chumphon province, Thailand |

| Raw materials | Palm oil mill effluent and decanter cake |

| Technology | A+ HCSR |

| Biogas production | 12,000 m3/d at full capacity |

| Gas utilization | Replacing 1.1 MW electricity – grid connection |

| Financial support | Energy Conservation Promotion Fund, Thailand |

Plant 10

10. Conceptual and engineering design

| Title | Infomation |

|---|---|

| Year | 2014 – 2015 |

| Company name | PALMCI Company |

| Location | Abidjan, Ivory Coast |

| Description | Conceptual and engineering design of a combined A+Ground Reactor – A+UASB – A+CHCR biogas system for the treatment of waste water and decanter cake from palm oil production; engineering design of an integrated biogas utilization system for heat and power generation taking into account seasonal variation of feedstock material. |

| System capacity | 20,000 m3/d at full capacity |

| Gas utilization | heat for boiler and 2 MWel power generation grid connected |

| Position/role | Consulting by Natural Power; 6 person-month |

Plant 11

11. Palm oil mill effluent management system

| Title | Infomation |

|---|---|

| Year | 2015 – 2017 |

| Company name | CPP Co., Ltd. |

| Location | Prachuap Khiri Khan province, Thailand |

| Raw materials | Palm oil mill effluent, production capacity of 45 tons FFB/hour or 1,080 tons FFB/d |

| Technology | A+ CHCR, A+ UASB |

| Biogas production | 25,000 m3/d at full capacity |

| Gas utilization | Produce Compressed Biomethane Gas (CBG) |

| Financial support | Private |

Plant 12

11. Conceptual design

| Title | Infomation |

|---|---|

| Year | 2018 |

| Company name | Biocosta Group: PALMAGRO S.A., ACEITES S.A., PALMACEITE S.A., EXTRACTORA EL ROBLE S.A.S and EXTRACTORA FRUPALMA |

| Location | Santa Marta, Colombia |

| Description | Assessment of the potential to apply biogas technology including conceptual design of appropriate biogas systems at 5 palm oil mills to improve environmental condition and the overall resource utilization management.; site inspection, feedstock analysis; options for biogas utilization. |

| Position/role | Consulting by Natural Power |