Technology

A+ CSTR

A+ UASB

A+ HCSR

A+ CHCR

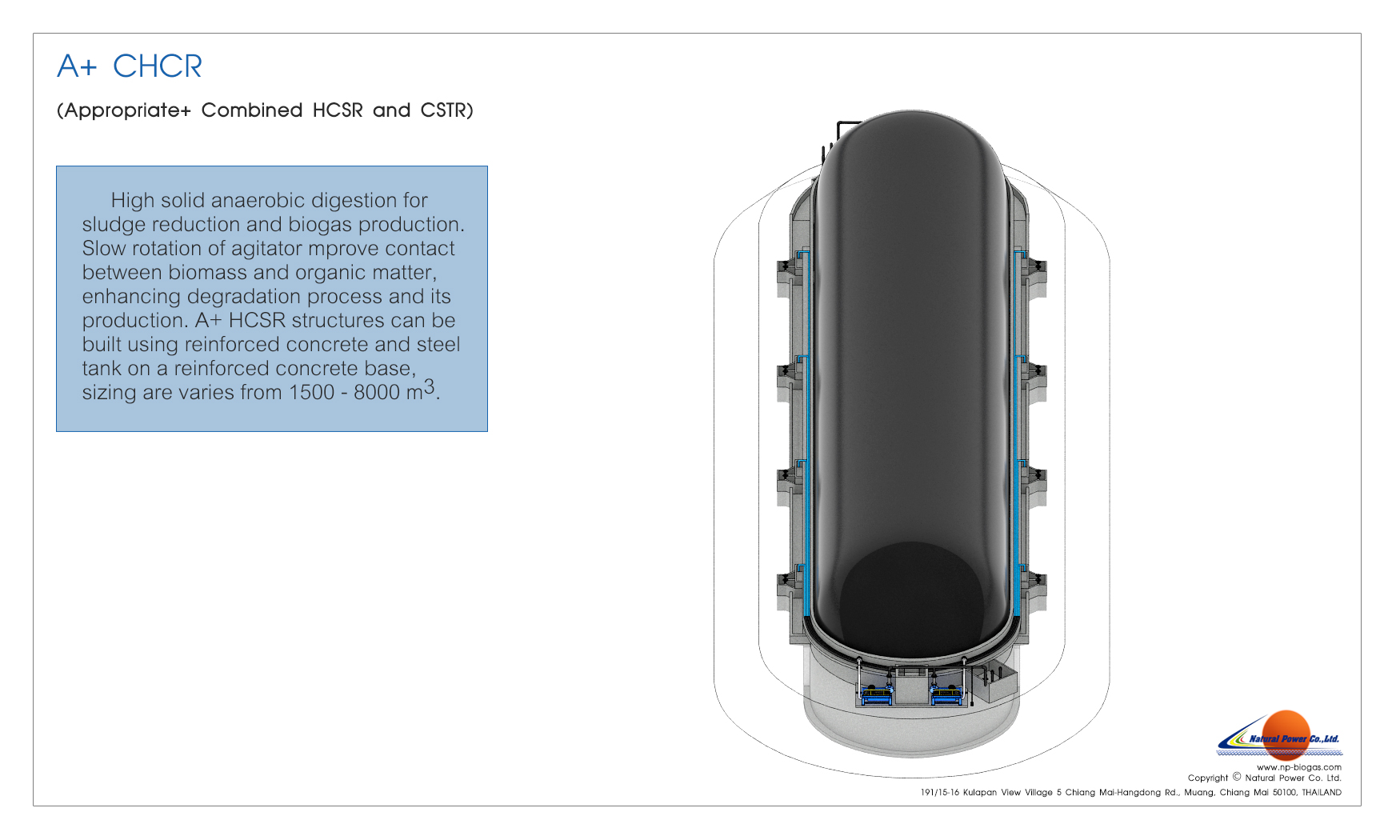

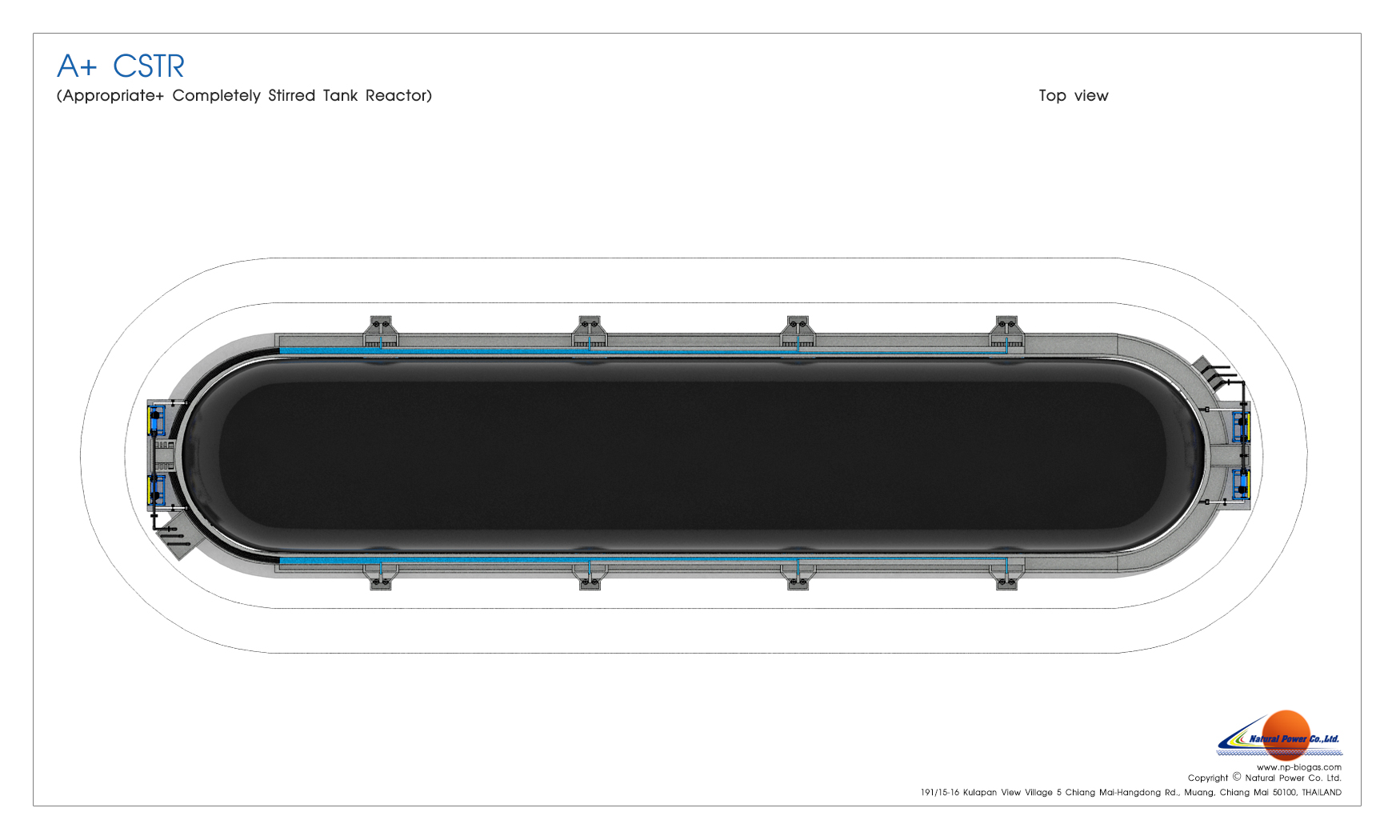

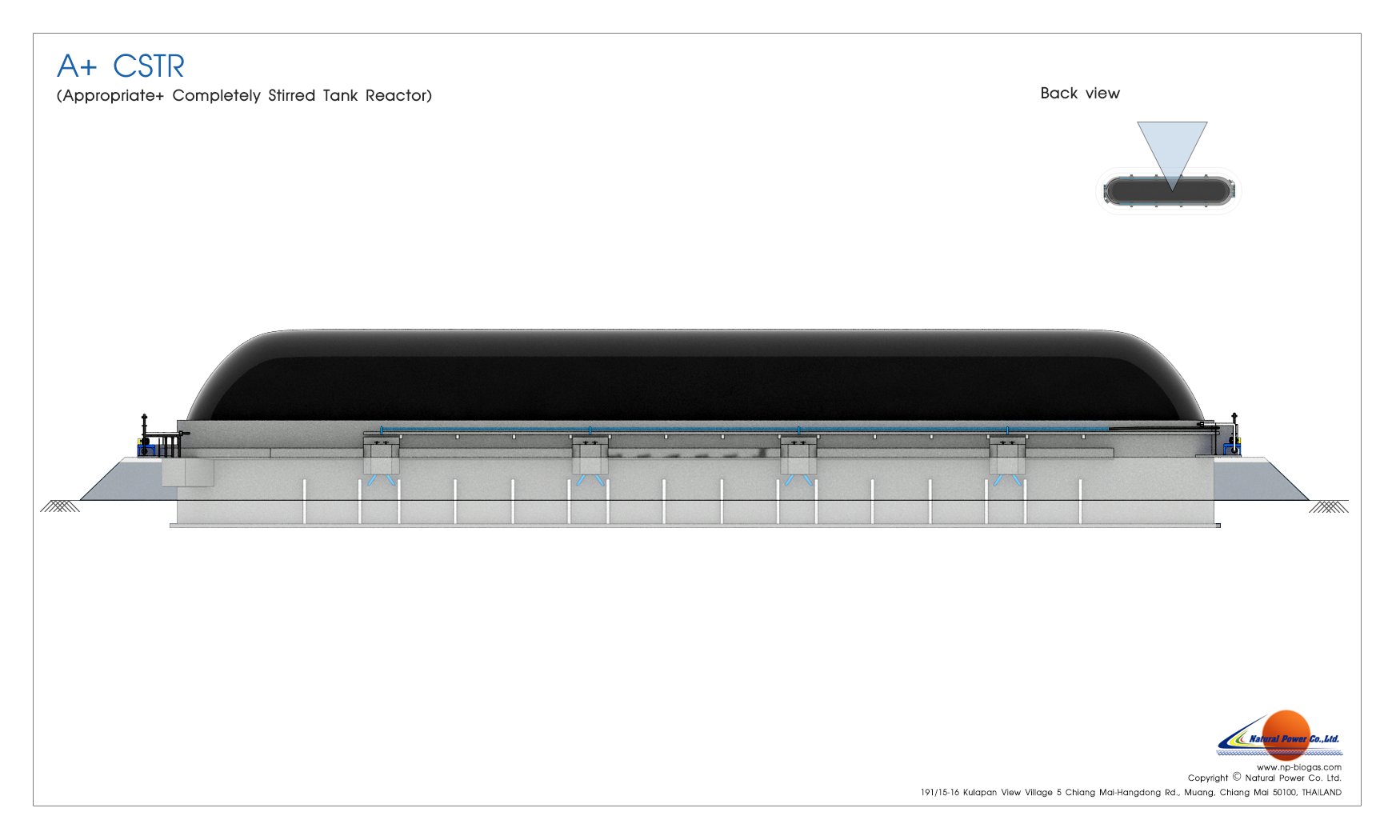

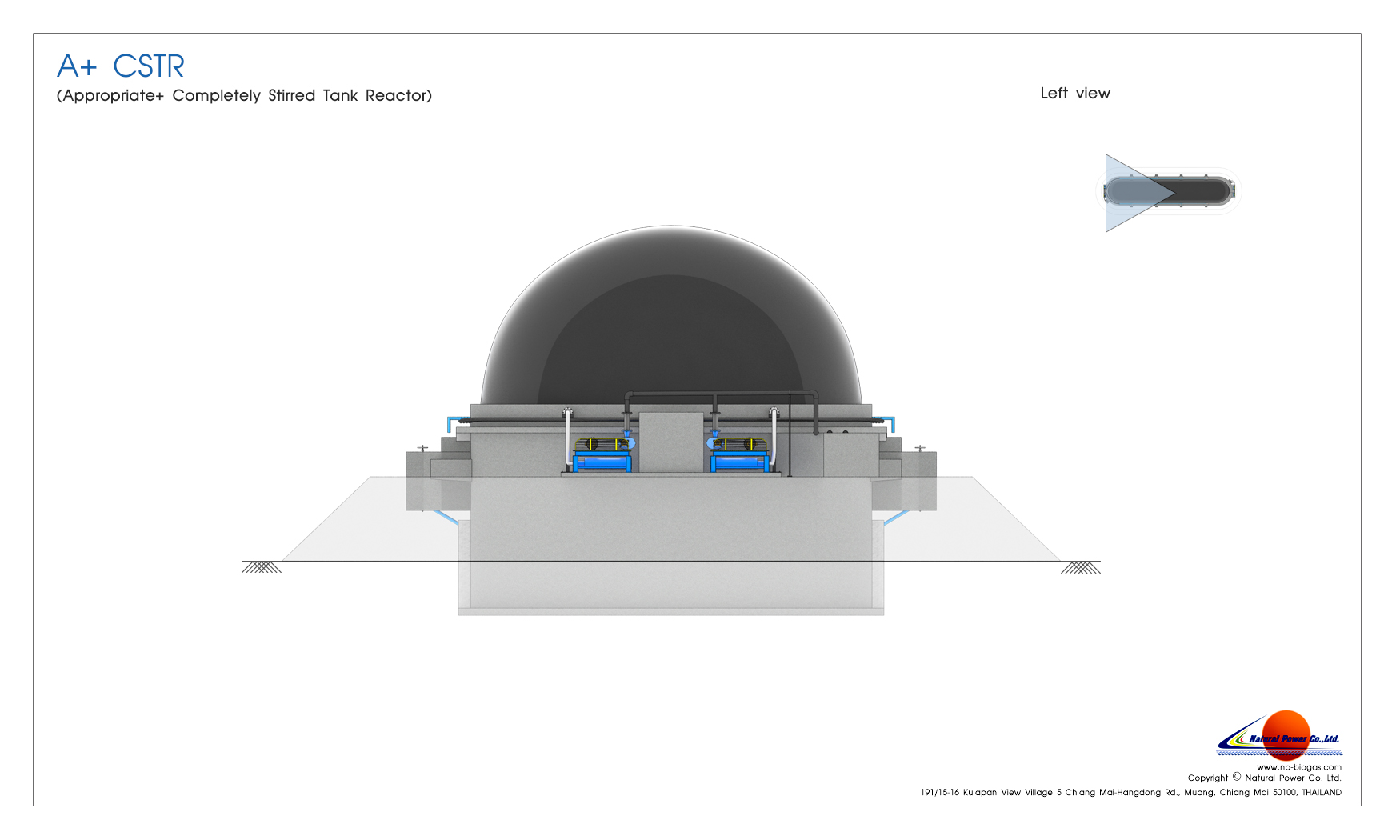

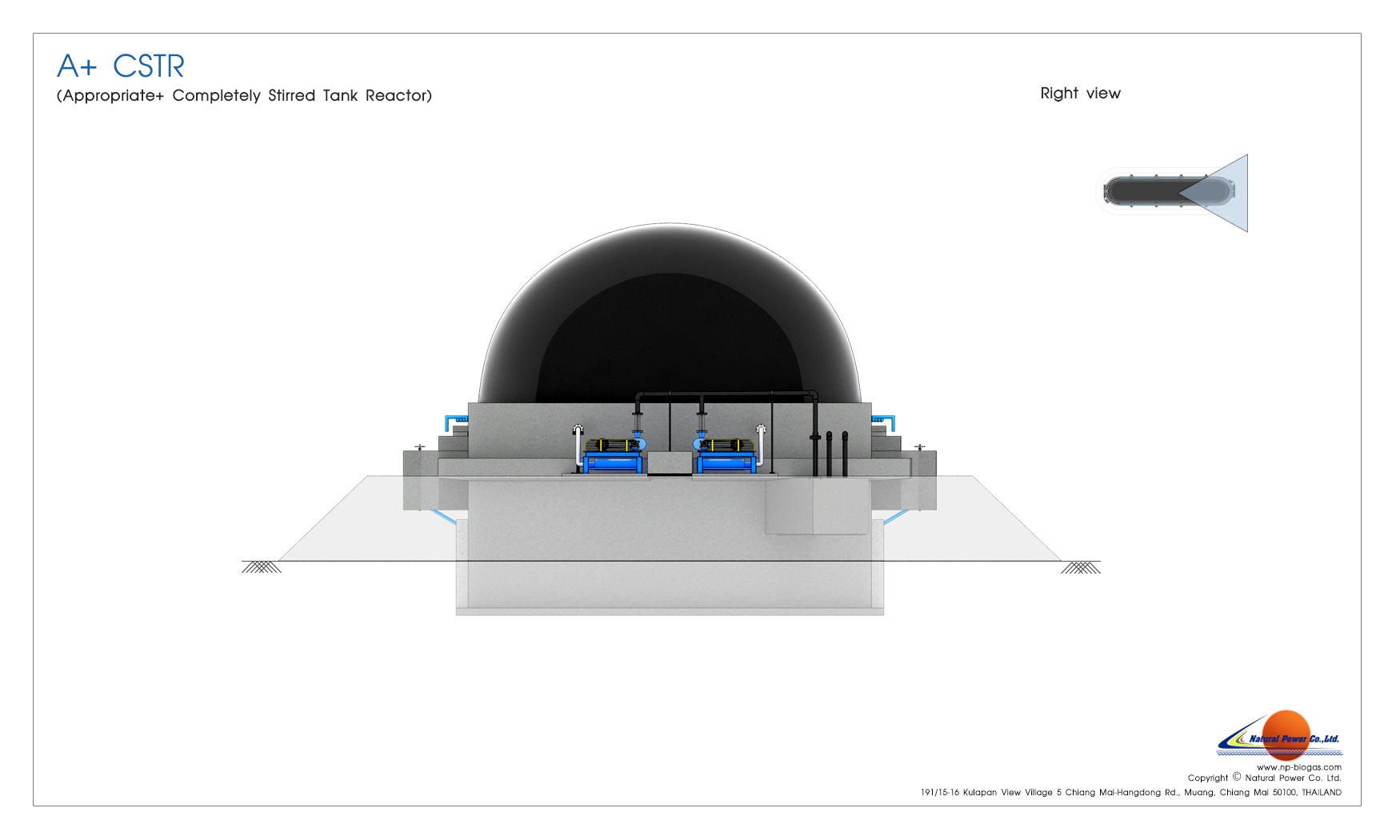

A+ CSTR

(Appropriate+ Completely Stirred Tank Reactor)

A+ CSTR has been developed by Natural Power Co., Ltd based on a Continuously Stirred Tank Reactor (CSTR) concept. This type of digester is suitable for the degradation of wastewater with high chemical oxygen demand (COD) and solids content. A+ CSTR operates in continuous flow mode where wastewater is continuously introduced and removed from the digester.

A+ CSTR can be made of both concrete and steel, constructed aboveground and/or partly underground. The size depends on volume of wastewater while maximum capacity can be ranged from 3000 – 5000 m3. In order to improve the biological reaction and avoiding dead zone, mixing tower is placed inside the digester. Efficient mixing within the digester enhance the interaction between sludge (bacteria) and wastewater (food) and maintaining good temperature control.

In such a digester, removal of inert sludge (dead cell and inorganic materials) can be done by gravity settling. This is to prevent their accumulation which decrease digester volume, affecting degradation rate and biogas production. This advanced technology can reduce up to 80 % of the initial COD and can produce 10,000 – 20,000 m3BG/d with 60 – 65 % methane. In addition, A+ CSTR act as gas storage where biogas generated is stored in the roof of digester (covered by PVC sheet).

Advantage

- Allow immediate contact between bacteria and food to enhanced degradation rate

- Enhance bacterial growth and mobility

- Flexible and robust for load variation

- Durable and long lifespan

- Inert sludge removed

- High removal efficiency

- High methane production

(Appropriate+ Completely Stirred Tank Reactor)

A+ CSTR has been developed by Natural Power Co., Ltd based on a Continuously Stirred Tank Reactor (CSTR) concept. This type of digester is suitable for the degradation of wastewater with high chemical oxygen demand (COD) and solids content. A+ CSTR operates in continuous flow mode where wastewater is continuously introduced and removed from the digester.

A+ CSTR can be made of both concrete and steel, constructed aboveground and/or partly underground. The size depends on volume of wastewater while maximum capacity can be ranged from 3000 – 5000 m3. In order to improve the biological reaction and avoiding dead zone, mixing tower is placed inside the digester. Efficient mixing within the digester enhance the interaction between sludge (bacteria) and wastewater (food) and maintaining good temperature control.

In such a digester, removal of inert sludge (dead cell and inorganic materials) can be done by gravity settling. This is to prevent their accumulation which decrease digester volume, affecting degradation rate and biogas production. This advanced technology can reduce up to 80 % of the initial COD and can produce 10,000 – 20,000 m3BG/d with 60 – 65 % methane. In addition, A+ CSTR act as gas storage where biogas generated is stored in the roof of digester (covered by PVC sheet).

Advantage

- Allow immediate contact between bacteria and food to enhanced degradation rate

- Enhance bacterial growth and mobility

- Flexible and robust for load variation

- Durable and long lifespan

- Inert sludge removed

- High removal efficiency

- High methane production

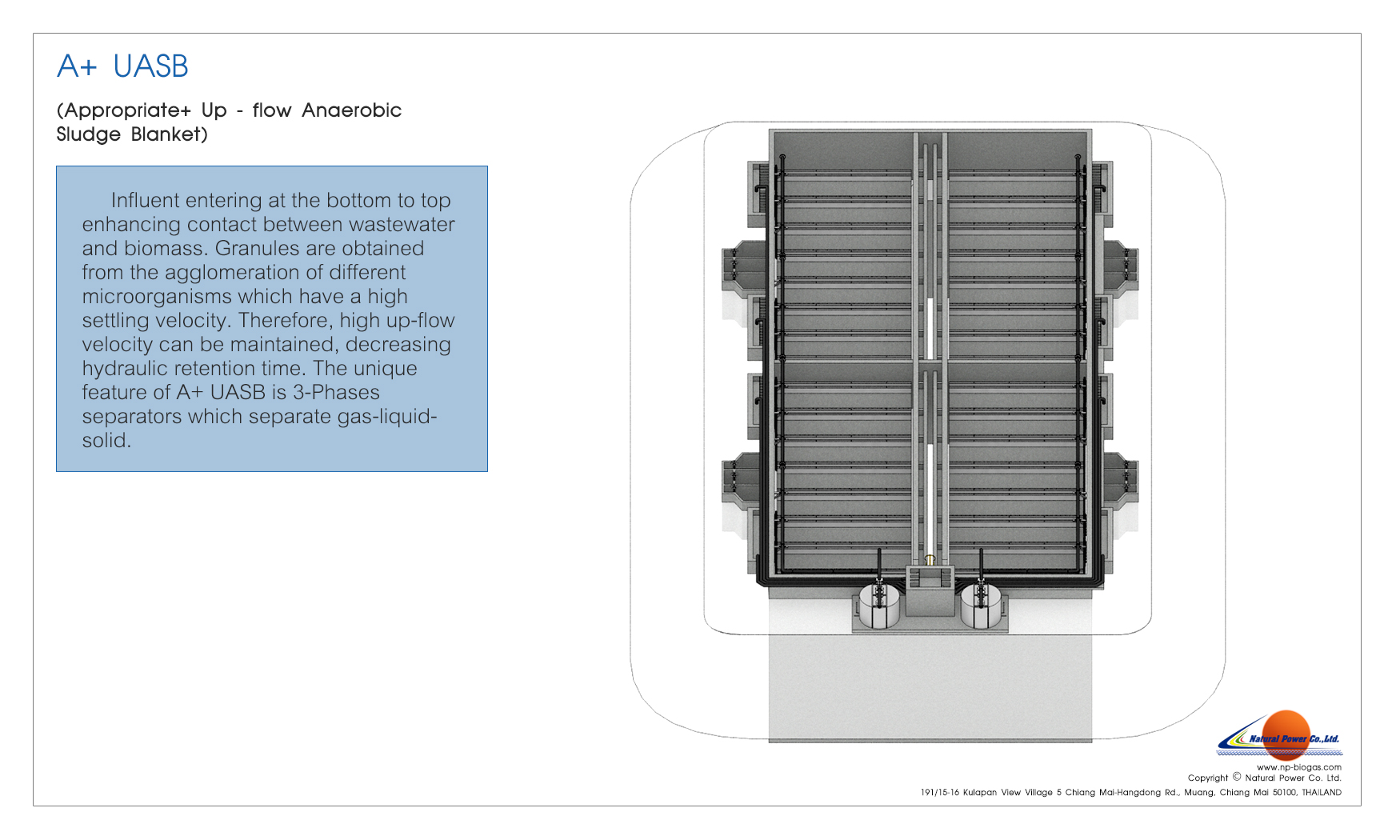

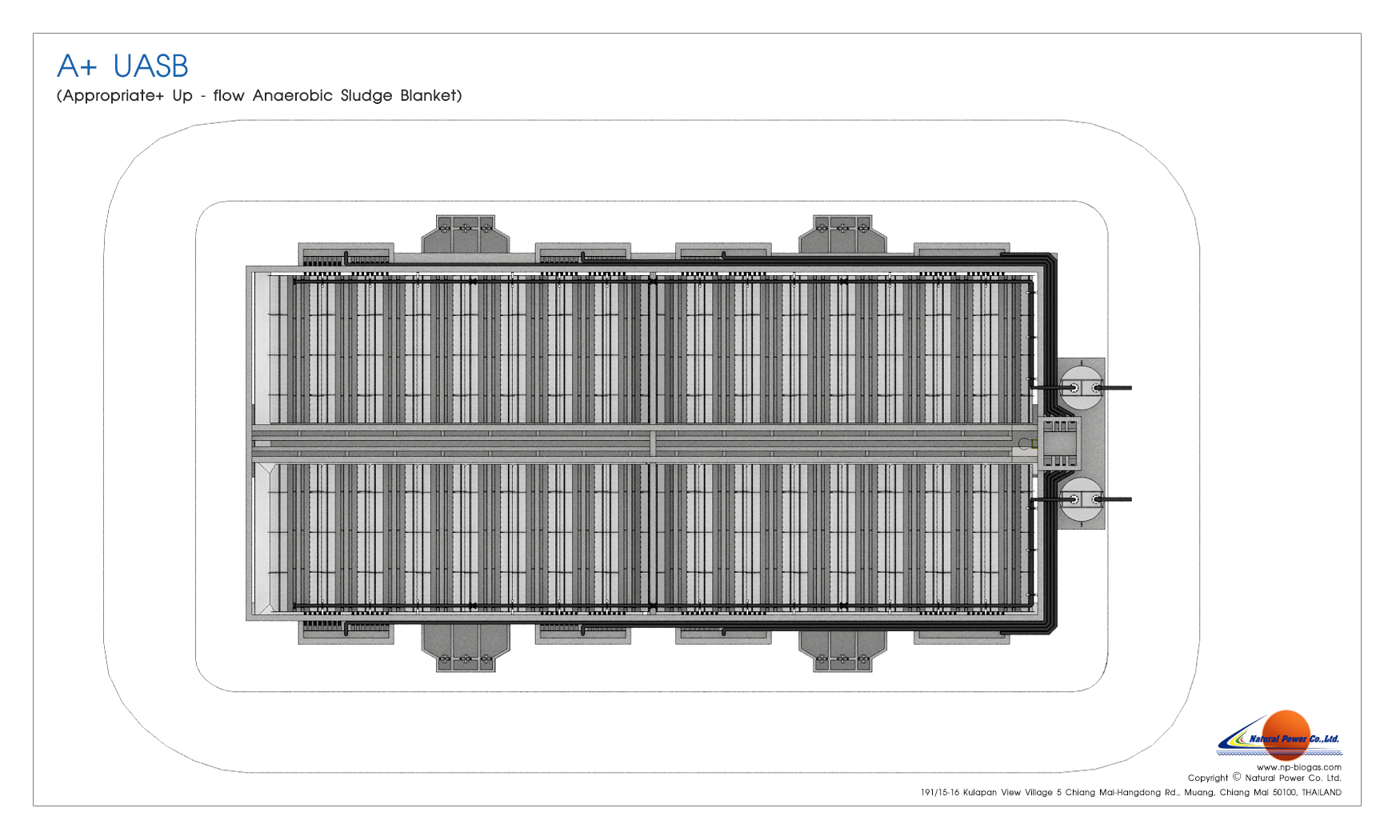

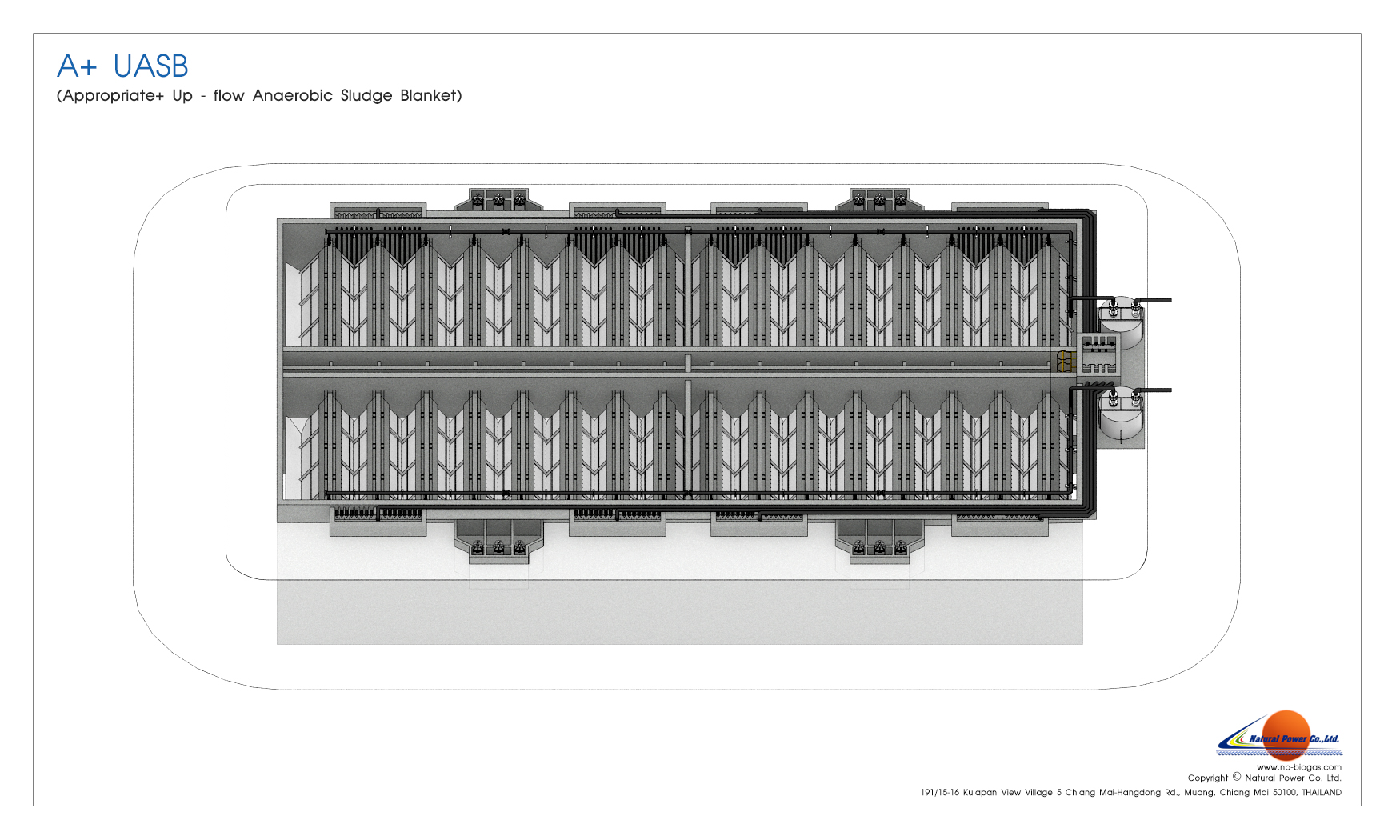

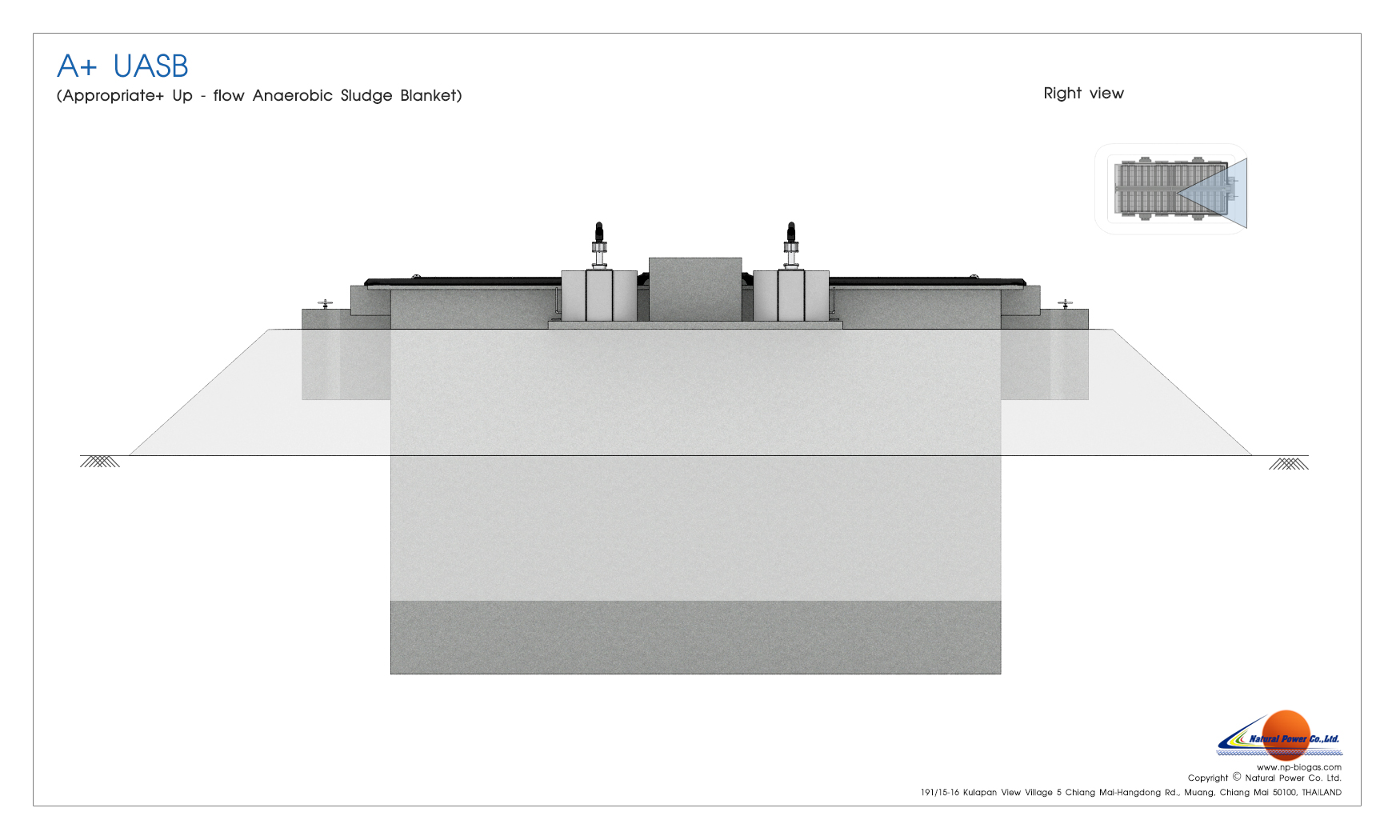

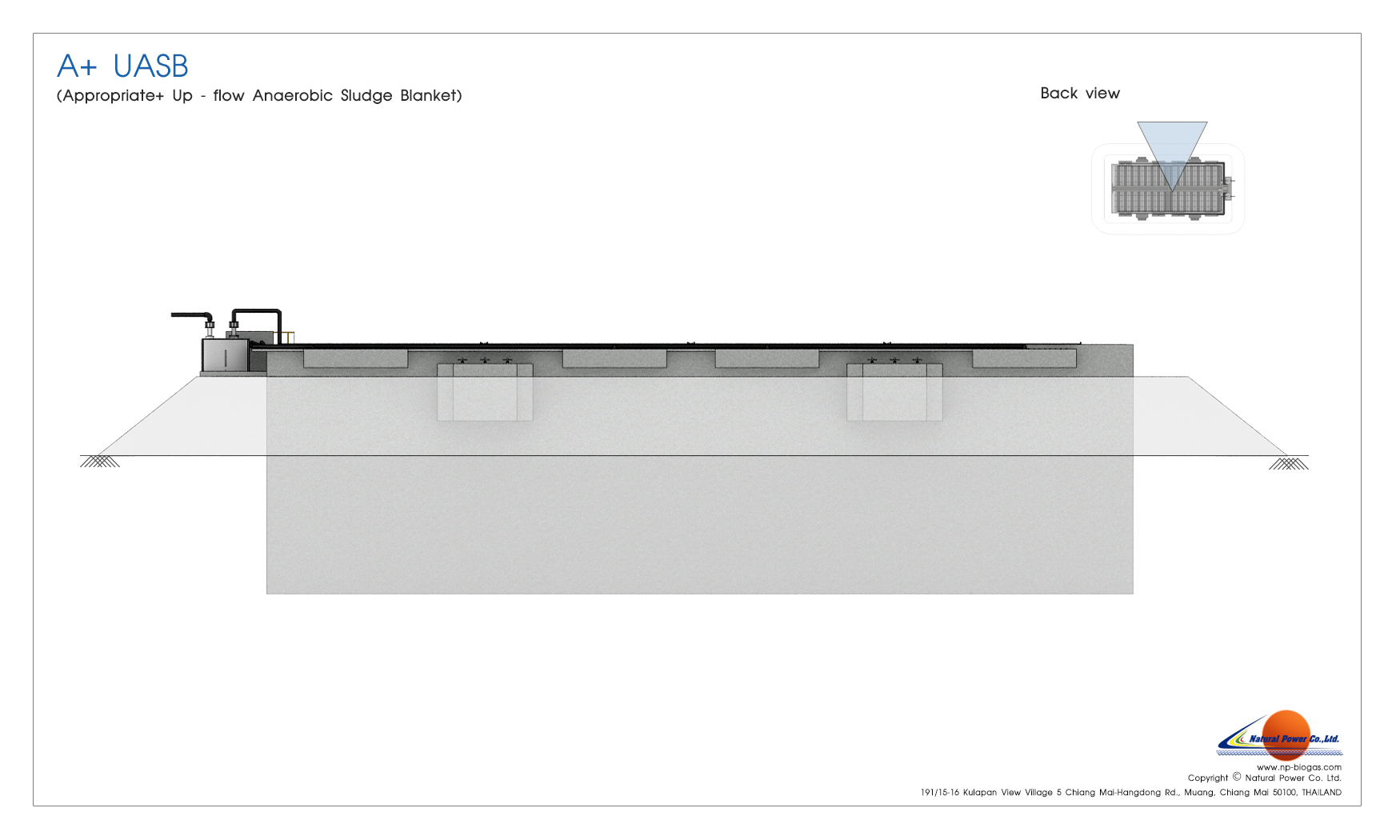

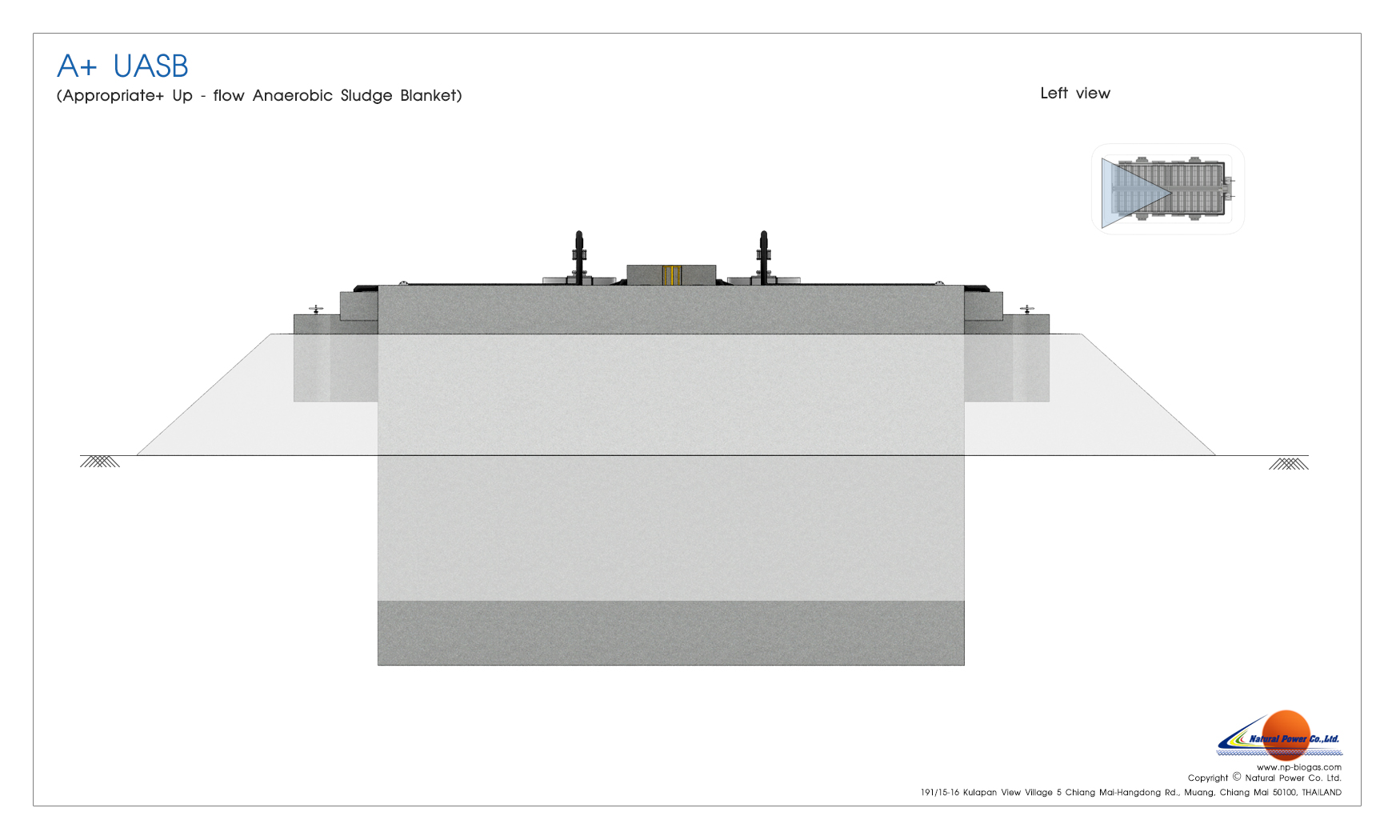

A+ UASB

(Appropriate+ Up – flow Anaerobic Sludge Blanket)

A+ UASB has been developed by Natural Power Co., Ltd, based on Up – flow Anaerobic Sludge Blanket (UASB) concept. This type of digester is suitable for the degradation of wastewater with low to medium chemical oxygen demand (COD) and solids concentration. In other words, effluent from A+ CSTR or other digester can be introduced to A+ UASB digester for further digestion for more biogas harvesting, COD and solids reduction.

A+ UASB is constructed out of concrete, constructed aboveground and/or partly underground while its size varies between 200 – 5000 m3. As an up – flow regime, granular forming organism are formed however, developing granular sludge may take several months. Feeding wastewater from the bottom allow good contact between sludge (bacteria) and wastewater (food) hence mechanical mixing is excluded. This type of technology can reduce up to 80 % of the initial COD and produce 400 – 5,000 m3BG/d with 65 – 70 % methane. An excellent settling characteristics of sludge in A+ UASB reactor, high up – flow velocity can be applied without washing out of biomass whereas provide a better contact between bacteria and food.

Advantage

- Provide good contact between bacteria and food

- Gas, solid and liquid separation

- Flexibility and durability

- Sludge retention time is independent from hydraulic retention time

- Virtually corrosion free and fireproof

- Inert sludge removed

- High removal efficiency

- High methane production

(Appropriate+ Up – flow Anaerobic Sludge Blanket)

A+ UASB has been developed by Natural Power Co., Ltd, based on Up – flow Anaerobic Sludge Blanket (UASB) concept. This type of digester is suitable for the degradation of wastewater with low to medium chemical oxygen demand (COD) and solids concentration. In other words, effluent from A+ CSTR or other digester can be introduced to A+ UASB digester for further digestion for more biogas harvesting, COD and solids reduction.

A+ UASB is constructed out of concrete, constructed aboveground and/or partly underground while its size varies between 200 – 5000 m3. As an up – flow regime, granular forming organism are formed however, developing granular sludge may take several months. Feeding wastewater from the bottom allow good contact between sludge (bacteria) and wastewater (food) hence mechanical mixing is excluded. This type of technology can reduce up to 80 % of the initial COD and produce 400 – 5,000 m3BG/d with 65 – 70 % methane. An excellent settling characteristics of sludge in A+ UASB reactor, high up – flow velocity can be applied without washing out of biomass whereas provide a better contact between bacteria and food.

Advantage

- Provide good contact between bacteria and food

- Gas, solid and liquid separation

- Flexibility and durability

- Sludge retention time is independent from hydraulic retention time

- Virtually corrosion free and fireproof

- Inert sludge removed

- High removal efficiency

- High methane production

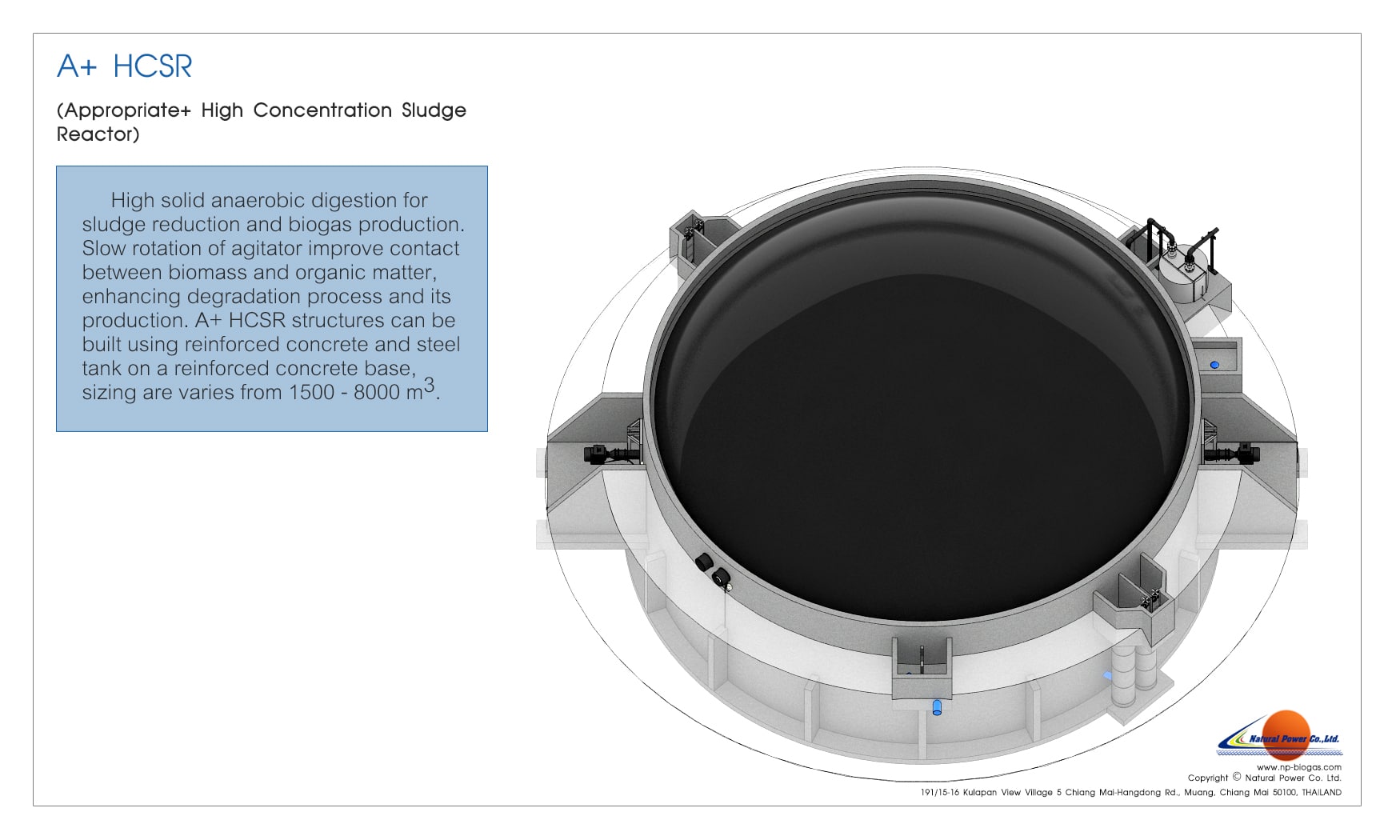

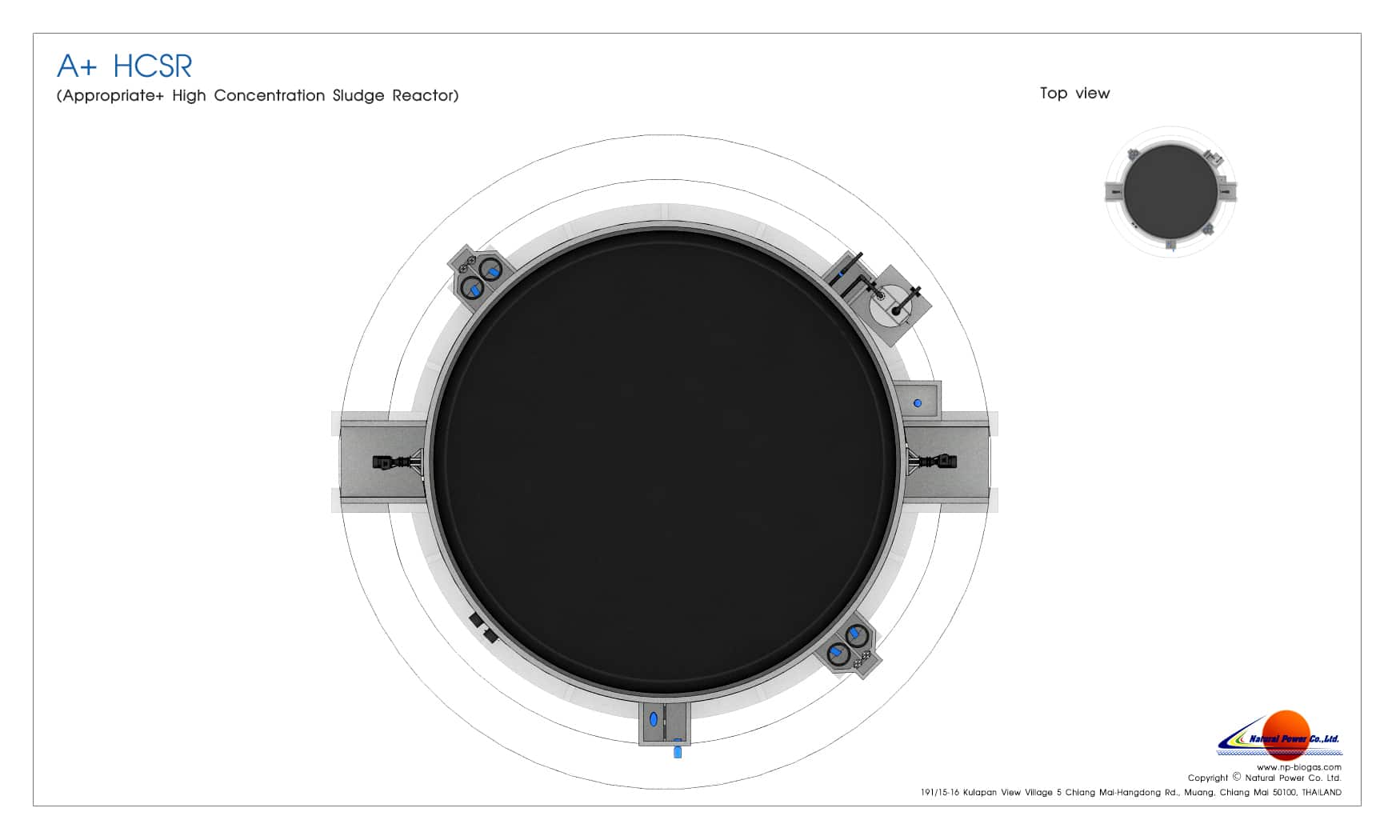

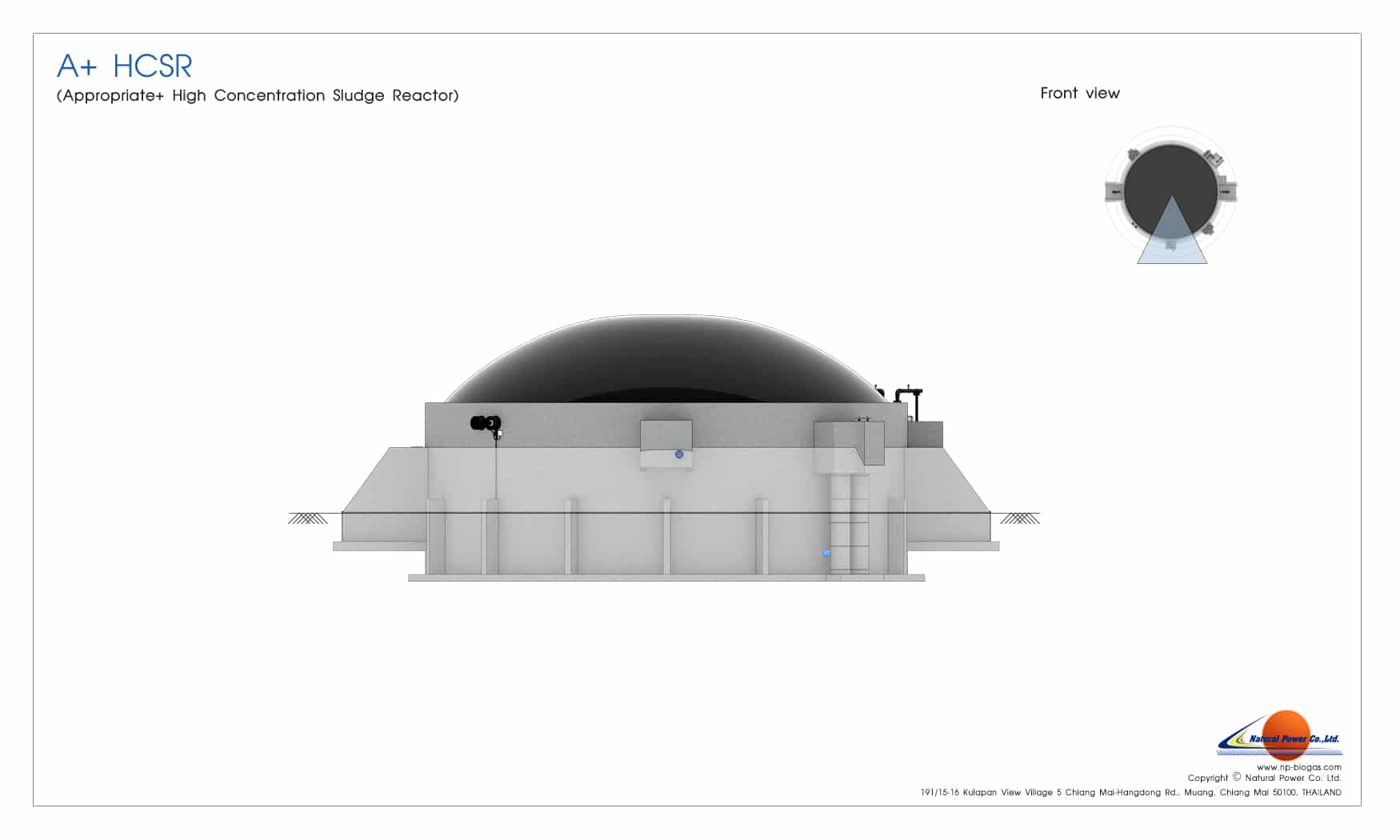

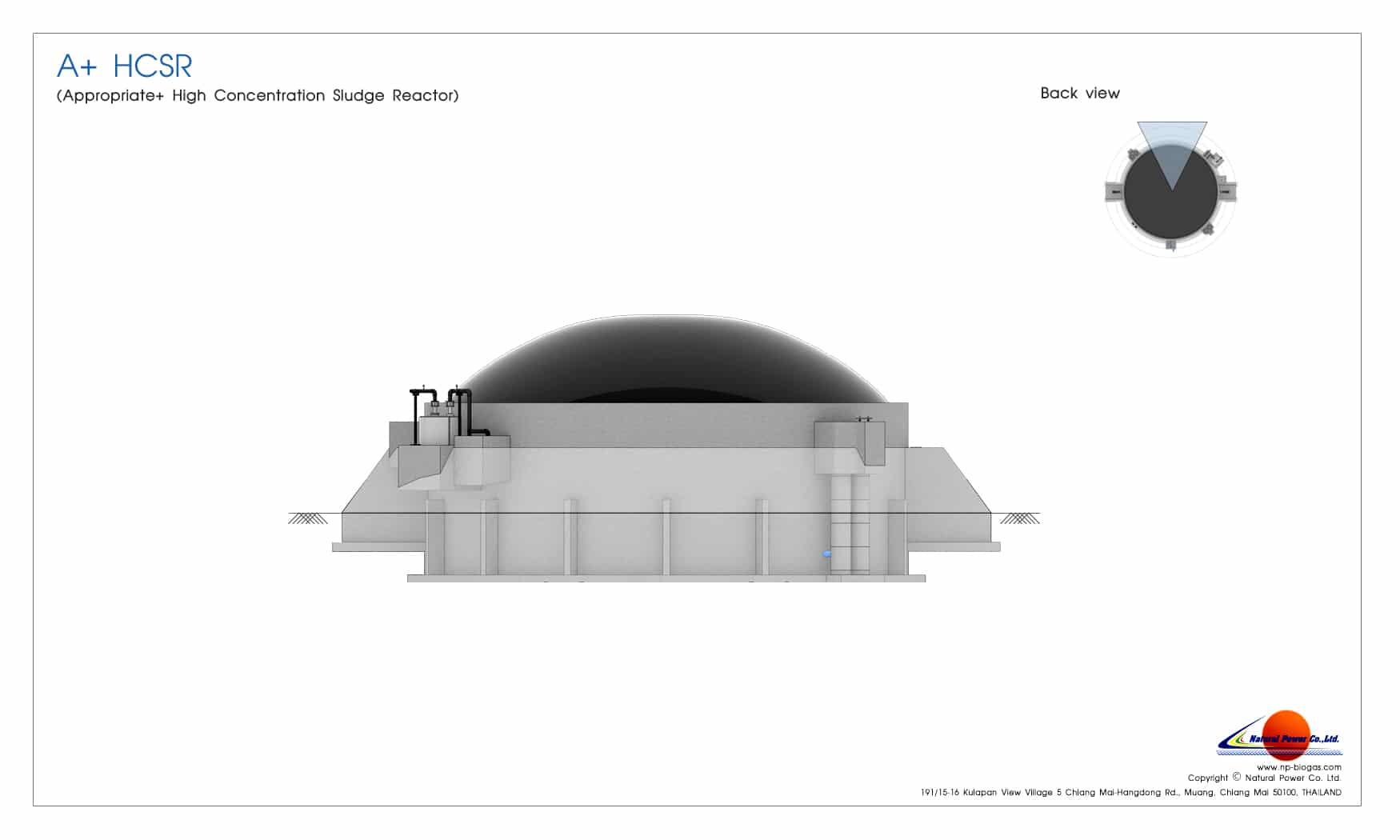

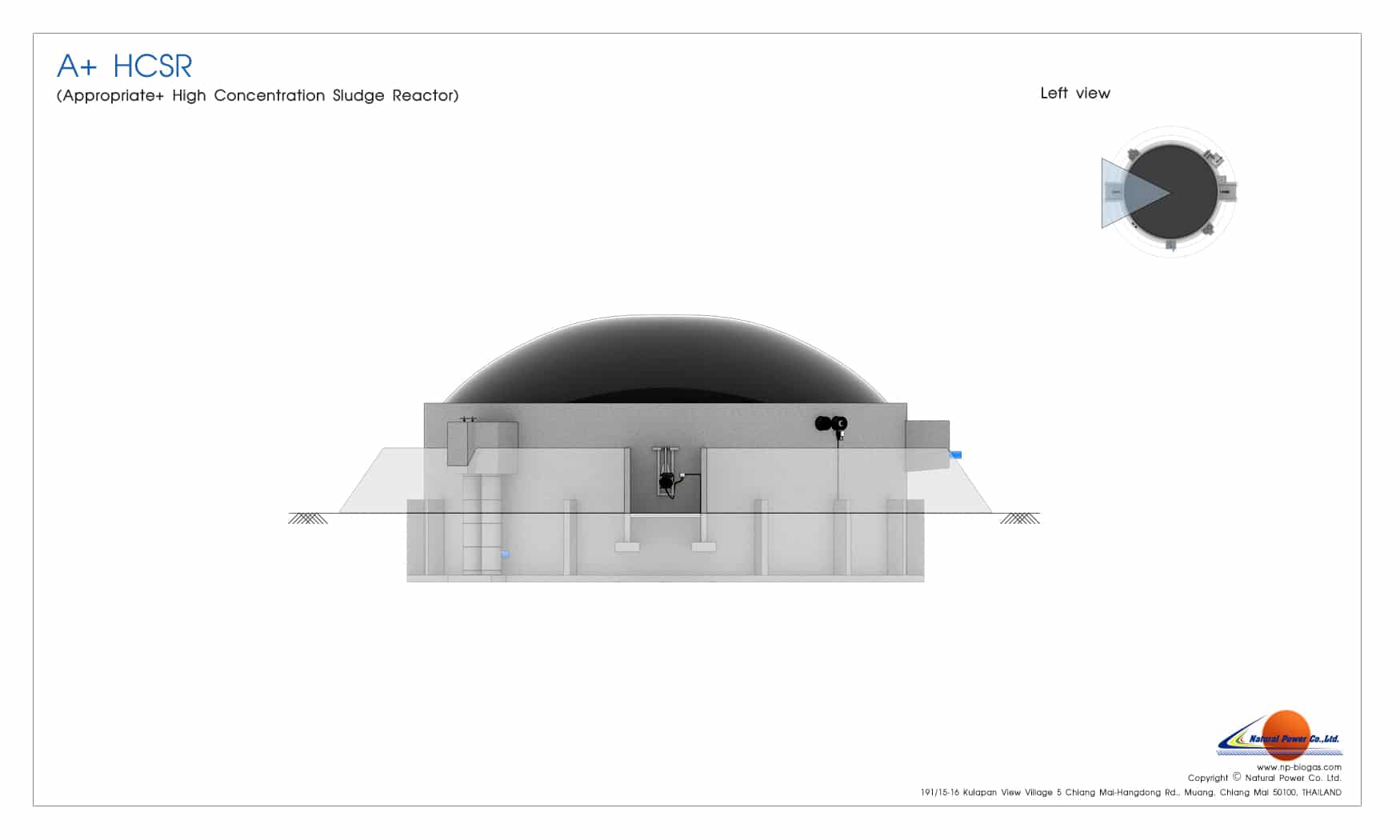

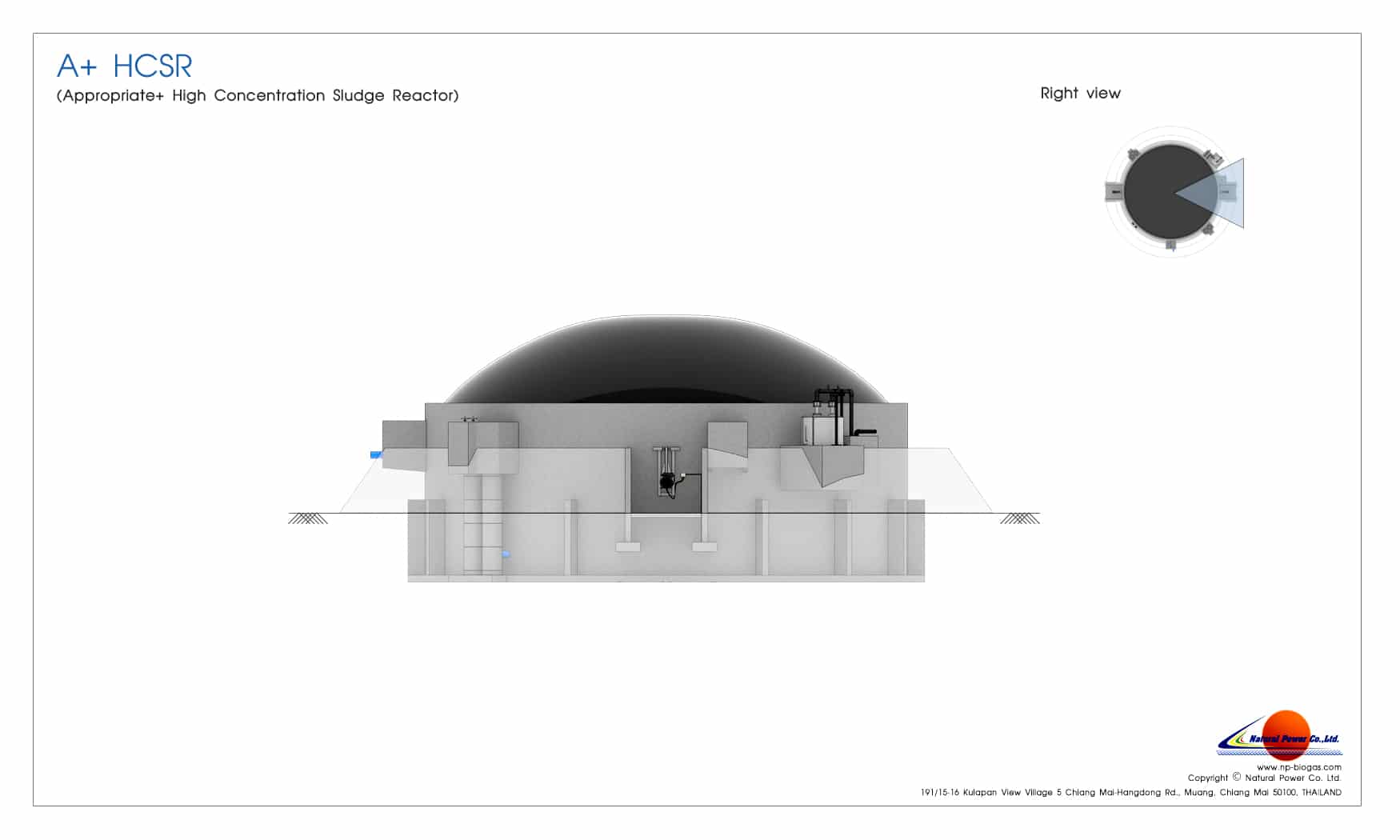

A+ HCSR

(Appropriate+ High Concentration Sludge Reactor)

A+ HCSR has been developed by Natural Power Co., Ltd, based on Continuously Stirred Tank Reactor (CSTR) concept. This type of digester is suitable for sludge with high concentration of suspended solids. Sludge from A+ CSTR, A+ UASB or others digester can be introduced into A+ HCSR with or without decanter cake for further digestion.

A+ HCSR is cylindrical reactor which can be made of both concrete or steel, constructed aboveground and/or partly underground. Size of the reactor is ranged between 1500 – 8000 m3. The slow rotation of agitator improves the contact between bacteria and organic matter, enhancing degradation process and biogas production. Biogas produced is captured and stored under the roof of A+ HCSR, which is covered by PVC sheet. This type of technology can produce up to 12,000 m3BG/d, usually contains about 65 % methane.

Advantage

- Suitable for sludge digestion

- Allow immediate contact between bacteria and food to enhanced degradation rate

- Flexibility and durability

- High methane production

(Appropriate+ High Concentration Sludge Reactor)

A+ HCSR has been developed by Natural Power Co., Ltd, based on Continuously Stirred Tank Reactor (CSTR) concept. This type of digester is suitable for sludge with high concentration of suspended solids. Sludge from A+ CSTR, A+ UASB or others digester can be introduced into A+ HCSR with or without decanter cake for further digestion. A+ HCSR is cylindrical reactor which can be made of both concrete or steel, constructed aboveground and/or partly underground. Size of the reactor is ranged between 1500 – 8000 m3. The slow rotation of agitator improves the contact between bacteria and organic matter, enhancing degradation process and biogas production. Biogas produced is captured and stored under the roof of A+ HCSR, which is covered by PVC sheet. This type of technology can produce up to 12,000 m3BG/d, usually contains about 65 % methane.Advantage

- Suitable for sludge digestion

- Allow immediate contact between bacteria and food to enhanced degradation rate

- Flexibility and durability

- High methane production

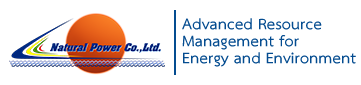

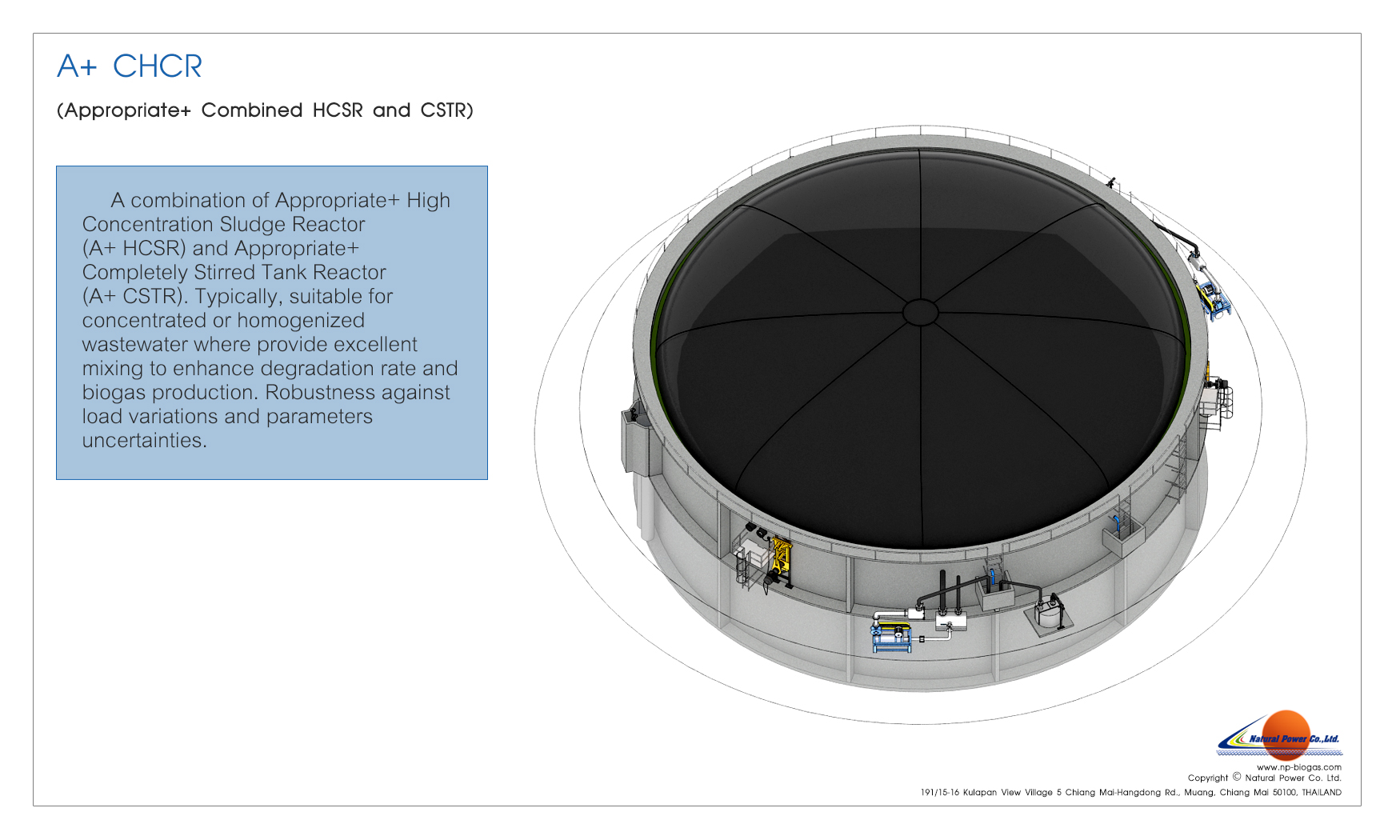

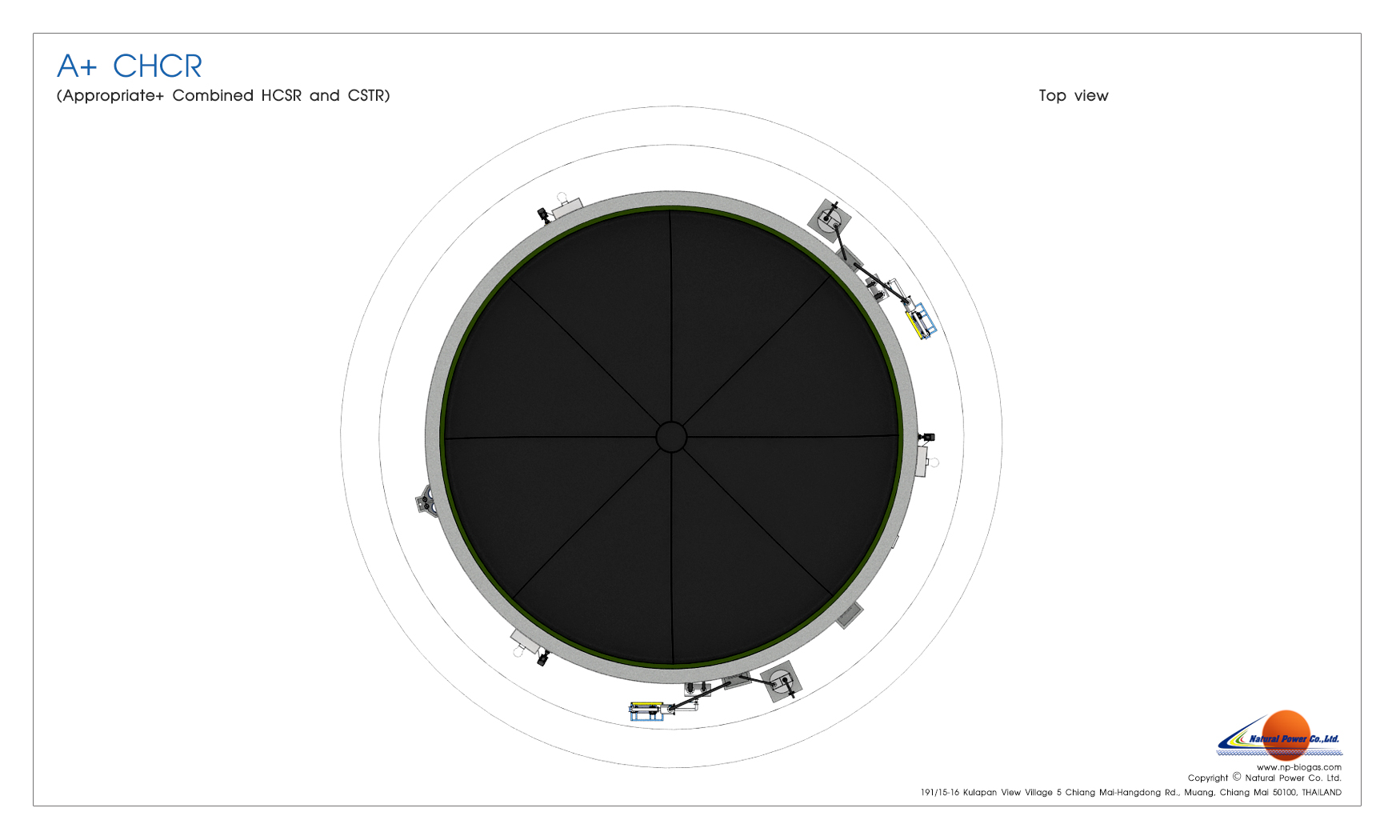

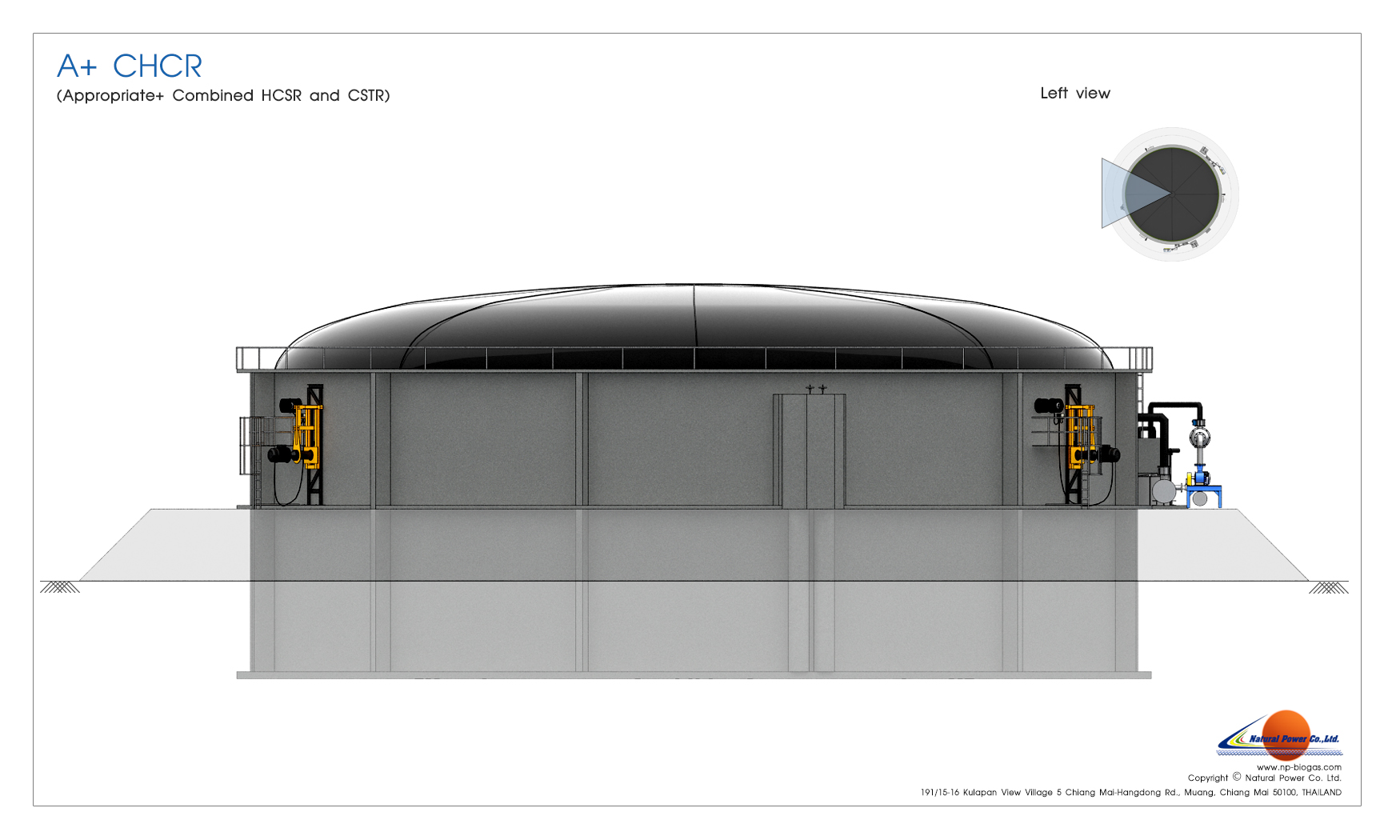

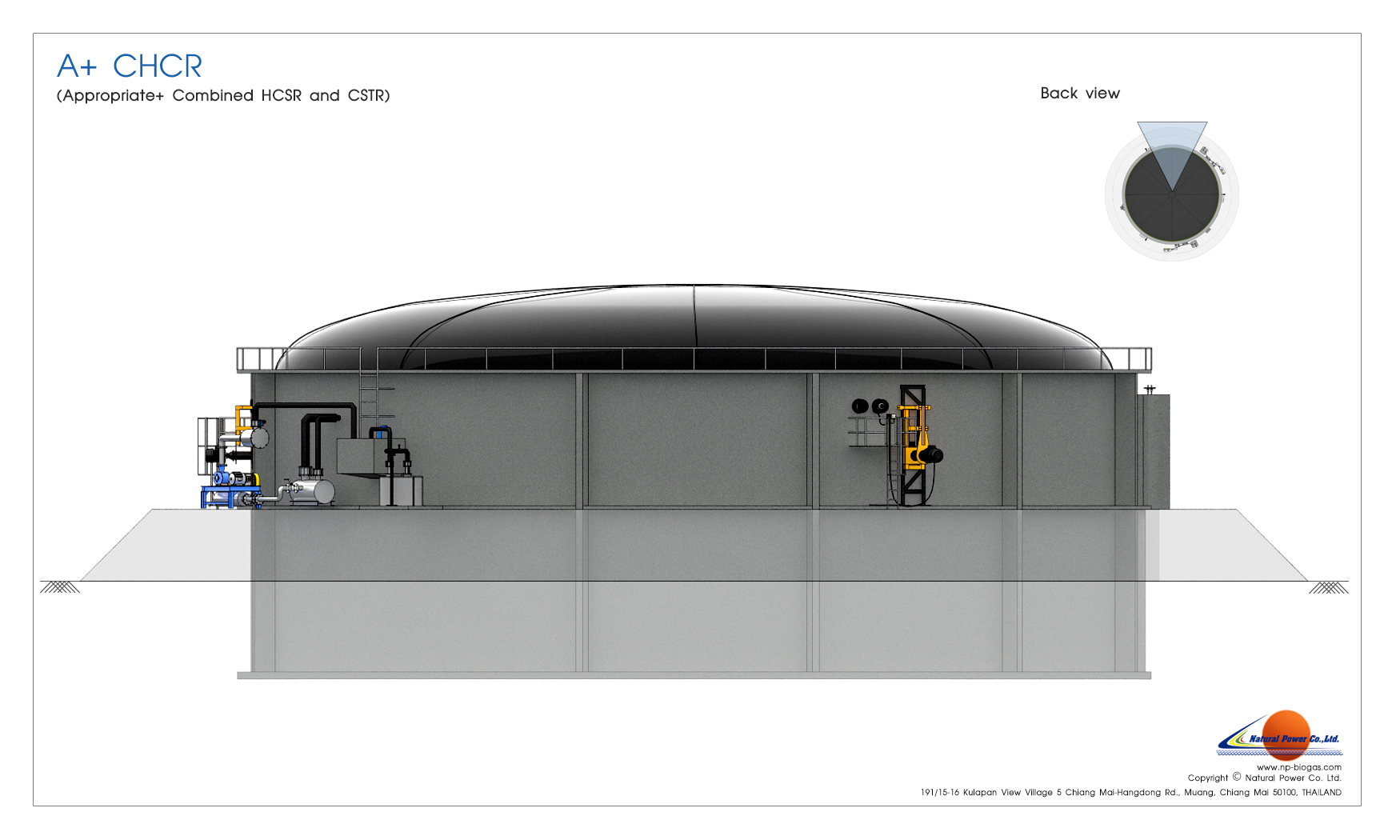

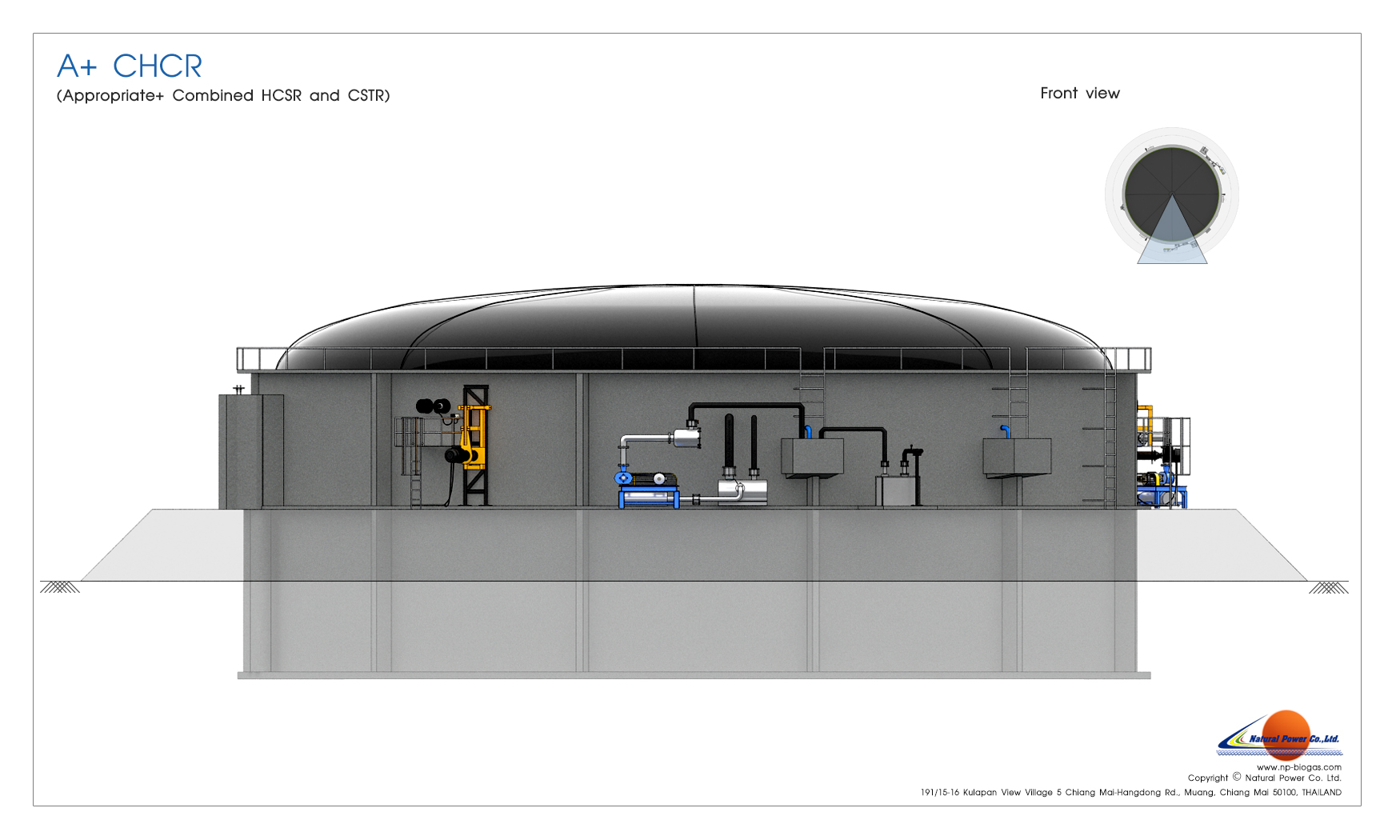

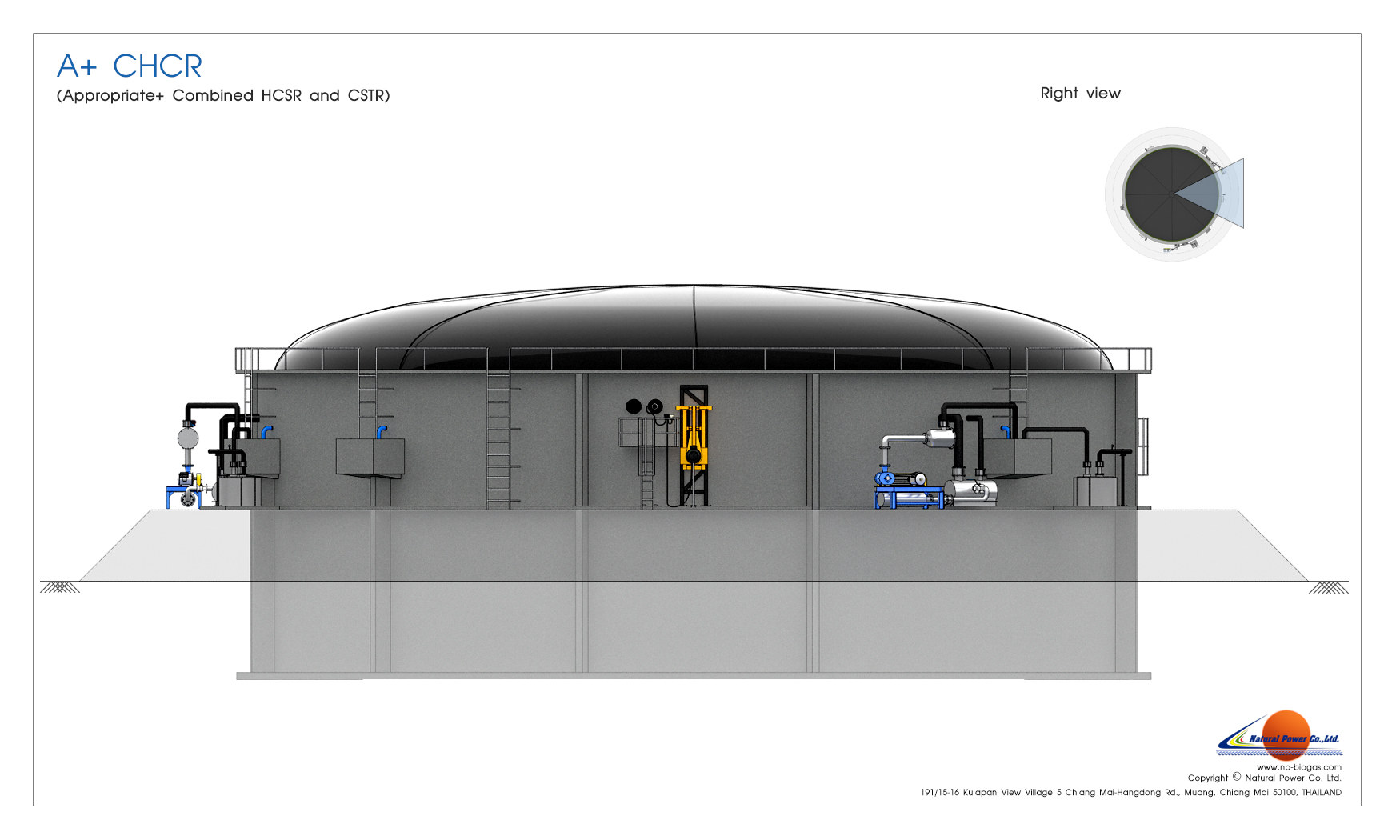

A+ CHCR

(Appropriate+ Combined HCSR and CSTR)

A+ CHCR is a combination of Appropriate+ High Concentration Sludge Reactor (A+ HCSR) with Appropriate+ Completely Stirred Tank Reactor (A+ CSTR) which is developed by Natural Power Co., Ltd for waste and wastewater management. This bioreactor is suitable for degradation of wastewater that contain a high concentration of suspended solids and COD and/or homogenized wastewater.

A+ CHCR can be made of steel and concrete constructed either aboveground or underground. The reactor is equipped with a robust slow moving agitator to provide homogeneity. As completely mixed system, circulation brings bacteria into contact with organic matter, enhancing the digester performance in both destructions of organic matter and biogas production. In addition, A+ CHCR Reactor acts as biogas storage where the produced biogas is stored under A+ CHCR cover sheet. A+ CHCR produce 10,000 – 20,000 m3BG/d with 60 % methane content.

Advantage

- Suitable for high concentrated wastewater

Allow immediate contact between bacteria Enhance bacterial growth and mobility

- Flexible and robust for load variation

- Durable and long lifespan

- Inert sludge removed

- High removal efficiency

- High methane production

(Appropriate+ Combined HCSR and CSTR)

A+ CHCR is a combination of Appropriate+ High Concentration Sludge Reactor (A+ HCSR) with Appropriate+ Completely Stirred Tank Reactor (A+ CSTR) which is developed by Natural Power Co., Ltd for waste and wastewater management. This bioreactor is suitable for degradation of wastewater that contain a high concentration of suspended solids and COD and/or homogenized wastewater.

A+ CHCR can be made of steel and concrete constructed either aboveground or underground. The reactor is equipped with a robust slow moving agitator to provide homogeneity. As completely mixed system, circulation brings bacteria into contact with organic matter, enhancing the digester performance in both destructions of organic matter and biogas production. In addition, A+ CHCR Reactor acts as biogas storage where the produced biogas is stored under A+ CHCR cover sheet. A+ CHCR produce 10,000 – 20,000 m3BG/d with 60 % methane content.

Advantage

- Suitable for high concentrated wastewater

Allow immediate contact between bacteria Enhance bacterial growth and mobility

- Flexible and robust for load variation

- Durable and long lifespan

- Inert sludge removed

- High removal efficiency

- High methane production